- Please select your vehicle fitment -

The ONLY Helical LSD on the market with hassle free variable-rate torque biasing

Working in partnership with OZ Performance Drivetrain of Australia, we have incorporated their patent-pending VTB system into our new v3 Helical LSD. Users can fine tune their own Bias Ratios at the track and at no additional cost, simply by adding/removing the included Swift coil springs. With the MFactory VTB LSD, up to 85% torque bias can be transferred to the wheel with traction! A must-have for serious circuit use. All MFactory VTB LSD's are pre-set to 75% torque bias (unless otherwise requested).

For the technically inclined:

- When driving in a straight line (or minute manoeuvring), torque will be split approximately 50/50 between the left/right axles and the internal gears of the differential will effectively be inoperational.

- If your vehicle axle speeds start to differentiate (i.e during cornering), the differential will compensate for this by biasing the axle speed of the faster spinning axle in direct proportion to the slower spinning axle. If the left axle is spinning 10% above nominal, the right axle will spin 10% slower as the left/right axles in the differential are locked together via the internal gears in opposing directions. 60% + 40% = 100%, with nominal being 50%.

- But if this is the case, then why would a vehicle that is stationary but spinning one wheel not move? This is because it is the differential housing that is providing the forward rotational movement (thus the spinning axle is rotating forward), with the stationary axle rotating backwards internally via the differential gears, effectively cancelling out the forward rotational movement of the differential housing.

- If you had 75% torque bias (TBR), this means that the spinning axle will receive 3 times the amount of torque of the stationary axle, but due to there being minimal torque transfer to the spinning axle (which has minimal or zero load, thus spinning purely on momentum), the stationary axle will not have enough torque to move the mass of the vehicle on it's own.

- This is where a pre-loaded differential comes into play. By pre-loading the internal gears of the differential, this simulates load on the axles, thus increasing the amount of torque being transferred through the differential. Once this increase in torque becomes sufficient enough to overcome the mass of the vehicle, the vehicle will start moving.

- This applies to ALL torque-biasing differentials, however, the implementation of the pre-load system is the differentiating factor between the various LSD's on the market

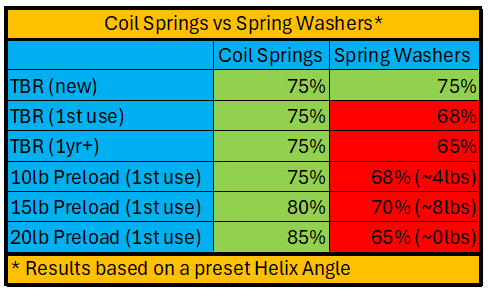

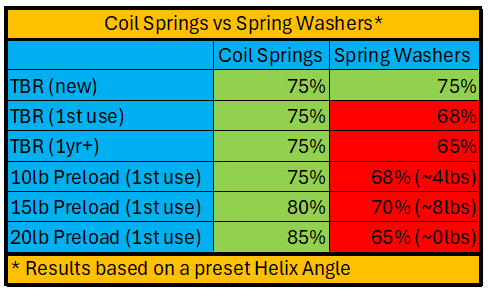

Swift Coil Springs

Unlike all other Helical LSD's on the market, the MFactory VTB LSD uses a coil spring pre-load system, NOT Belleville spring washers. Our Swift coil springs provide a smoother transition of load and do not lose their spring rate like spring washers do.

As can be seen from the comparison chart above, a Helical LSD that uses Belleville spring washers to pre-load the internals will lose 10% of it's torque-biasing effect after the 1st use! What's more, due to dimensional restrictions (there are no dimensional restrictions with coil springs), the more pre-load you add with additional washers (short of turning the LSD into a spool), the less TBR you will achieve.

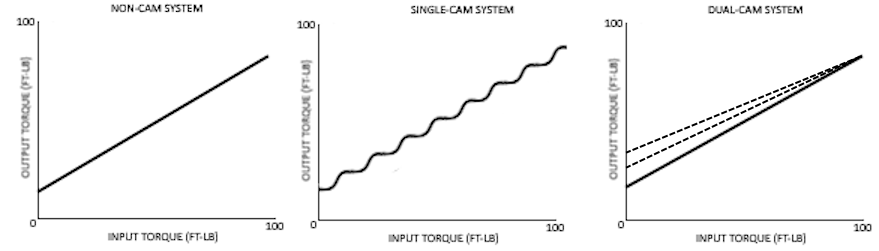

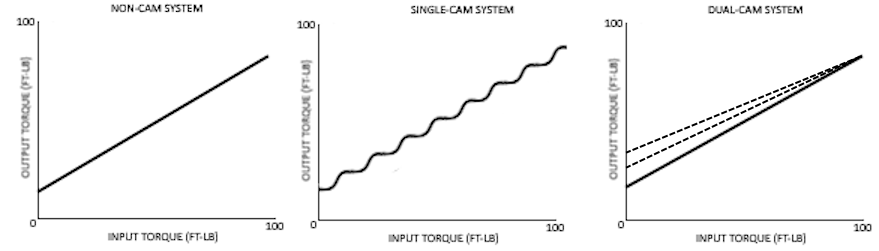

Dual-Pulsing Cams* (for those of you located in the US, Australia or Japan, please read our important legal disclaimer)

With the patent-pending VTB system, which utilizes dual-pulsing cam technology, both axles are drive-locked to the VTB cam, yet can still rotate independently of each other (unlike a Spool), similar to a regular Helical LSD. Due to being in a 100% constant state of torque-biasing, the MFactory VTB LSD will function both on & off throttle, similar to a Plate-type LSD.

By changing the ramp angles on the cam, the ramp-up response rate can also be fine-tuned. Whilst the maximum pre-load amount will not change, a more aggressively angled ramp will pre-load the system quicker, resulting in a significantly increased amount of torque transferred to the wheels up to the maximum as determined by the TBR. Initially set at 35deg, we will be offering more aggressive angles in the near future.

The above comparison chart details the difference between a Non-Cam system (the majority of Torque Biasing Differentials), a Single-Cam system and a Dual-Cam system (OZ Performance Drivetrain VTB System). As can be seen from the chart, a Single-Cam system has significant issues with ramp-up response and how it delivers pre-load into the system. So much so that even a Non-Cam system will provide smoother and more predictable power delivery to the wheels, provided there isn't a low-load/zero-load situation occurring. The dotted lines on the Dual-Cam graph give an example of more aggressive ramp-up response angles.

No-Load/One-Wheel Syndrome

A common misconception is that a torque-biasing Differential is useless under a no-load situation (e.g One wheel in the air). Although true to an extent, this no-load situation does not apply to the modern day car with Traction Control (or eDiff). For those without traction control, there is a very commonly used solution to the problem (used by professional race car drivers over the past 30+ years) that our competitors will not tell you; simply left-foot brake. Of course, with the MFactory VTB LSD, this is not an issue, with or without traction control due to our use of Dual-Pulsing cam technology.

Additionally, a Single-Cam system will only function consistently on one wheel during a low-load/zero-load situation, dependent on which axle the cam is driving. Due to the opposing axle functioning via a friction-based mechanism, this is rather hit-and-miss, as proven by real-world performance reviews. In most FWD vehicles, the cam will be driving the left axle (right axle on Honda B-Series). What this means is that, if your right axle (left axle on Honda B-Series) is subject to a low-load/zero-load situation, there is a significant chance of losing all power to your drivetrain, similar to a Non-Cam torque-biasing differential or Open Differential. With a Dual-Cam system, this will never be an issue as drive will always be provided to both axles, much like a Plate LSD would.

The MFactory VTB LSD is the ONLY Helical LSD on the market that is a true hybrid of a Helical LSD (smoothness, noise-free, maintenance-free) and a Plate-type LSD (variable torque/load settings, increased traction under most situations).

To enhance durability whilst minimising frictional losses, all MFactory VTB LSD's incorporate our proprietary nano-coated discs between the gears and LSD housing. Whilst most common Helical and Plate-type LSD's on the market will lose performance over time, the MFactory VTB LSD will provide the same level of performance over the lifetime of the LSD. And, unlike our competitors that use Carbon as their go-to friction material, our proprietary nano-coated discs only marginally reduce the friction co-efficient. Torque-biasing differentials by design rely on friction to generate torque, therefore using Carbon friction material to reduce friction by several magnitudes is truly a very bad idea. Infact, a mere 0.1 reduction in friction co-efficient is equivalent to a 10% reduction in TBR.

Hybrid Ceramic Bearing Technology (Application Dependant)

Depending on application, the MFactory VTB LSD will be supplied with our new Hybrid Ceramic Diff Bearings. Not only are our bearings stronger and more durable, they also offer the epitome of near-zero rotational friction, minimizing parasitic drivetrain losses, thus transferring more power to the ground!

3rd Generation Design

The MFactory VTB LSD is lighter, stronger and more efficient than any other Torque-Biasing Differential on the market today!

VTB System Upgrade (Application Dependant)

Already run a regular Helical LSD and were thinking of upgrading? For select applications, we are proud to offer our patent-pending VTB System as an independent aftermarket upgrade to existing MFactory Helical LSD's. The upgrade kit includes: VTB System + VTB Gears + New Case Bolts.

Diamond Cut to exacting tolerances from Forged High-Nickel-Chromium-Molybdenum Steel

Perfect fitment & finish ensures hassle-free installation & maintenance, each and every time.

Designed using leading-edge Solidworks 3D CAD & Cosmos FEA software

Advanced Gear Geometry minimizes parasitic drivetrain losses. Race transmissions built with MFactory components transfer, on average, 1-2% more power to the ground over our competitors!

Covered by the MFactory Lifetime, Globally Transferable Warranty

Whether used on the Street, Strip or Track, all MFactory VTB LSD's come with a Lifetime, No-Hassle, Globally Transferable Warranty.

Maintain a leading advantage over the competition with the patent-pending MFactory "Variable Torque Biasing" Limited Slip Differential. Through the smooth and constant distribution of power to the wheels, the MFactory VTB LSD puts the power-to-the-ground and maximises your vehicle's traction. A must for any race car, be it Street, Strip or Track!

Specifications

Honda B16A2 Fitments: Will not directly fit models previously equipped with an OEM Viscous LSD, and will require a Ring Gear change

BMW 135i MT/335i 07+ MT/DCT/335d Fitments: Will not directly fit these models due to the oem Ring Gear being welded onto the differential. The Ring Gear will either need to be machined to accept the new LSD, or a new bolted Ring & Pinion used. MFactory Competition Products is one of only 3 companies in the US that can provide this service that meets oem tolerances, and the only US company to manufacture precision aftermarket performance Ring & Pinions (Final Drive Gears) for the BMW

PLEASE NOTE:

Our VTB LSD is still under development and is not yet ready to be released to market. Please Contact Us for an ETA before placing your order

Working in partnership with OZ Performance Drivetrain of Australia, we have incorporated their patent-pending VTB system into our new v3 Helical LSD. Users can fine tune their own Bias Ratios at the track and at no additional cost, simply by adding/removing the included Swift coil springs. With the MFactory VTB LSD, up to 85% torque bias can be transferred to the wheel with traction! A must-have for serious circuit use. All MFactory VTB LSD's are pre-set to 75% torque bias (unless otherwise requested).

For the technically inclined:

- When driving in a straight line (or minute manoeuvring), torque will be split approximately 50/50 between the left/right axles and the internal gears of the differential will effectively be inoperational.

- If your vehicle axle speeds start to differentiate (i.e during cornering), the differential will compensate for this by biasing the axle speed of the faster spinning axle in direct proportion to the slower spinning axle. If the left axle is spinning 10% above nominal, the right axle will spin 10% slower as the left/right axles in the differential are locked together via the internal gears in opposing directions. 60% + 40% = 100%, with nominal being 50%.

- But if this is the case, then why would a vehicle that is stationary but spinning one wheel not move? This is because it is the differential housing that is providing the forward rotational movement (thus the spinning axle is rotating forward), with the stationary axle rotating backwards internally via the differential gears, effectively cancelling out the forward rotational movement of the differential housing.

- If you had 75% torque bias (TBR), this means that the spinning axle will receive 3 times the amount of torque of the stationary axle, but due to there being minimal torque transfer to the spinning axle (which has minimal or zero load, thus spinning purely on momentum), the stationary axle will not have enough torque to move the mass of the vehicle on it's own.

- This is where a pre-loaded differential comes into play. By pre-loading the internal gears of the differential, this simulates load on the axles, thus increasing the amount of torque being transferred through the differential. Once this increase in torque becomes sufficient enough to overcome the mass of the vehicle, the vehicle will start moving.

- This applies to ALL torque-biasing differentials, however, the implementation of the pre-load system is the differentiating factor between the various LSD's on the market

Swift Coil Springs

Unlike all other Helical LSD's on the market, the MFactory VTB LSD uses a coil spring pre-load system, NOT Belleville spring washers. Our Swift coil springs provide a smoother transition of load and do not lose their spring rate like spring washers do.

As can be seen from the comparison chart above, a Helical LSD that uses Belleville spring washers to pre-load the internals will lose 10% of it's torque-biasing effect after the 1st use! What's more, due to dimensional restrictions (there are no dimensional restrictions with coil springs), the more pre-load you add with additional washers (short of turning the LSD into a spool), the less TBR you will achieve.

Dual-Pulsing Cams* (for those of you located in the US, Australia or Japan, please read our important legal disclaimer)

With the patent-pending VTB system, which utilizes dual-pulsing cam technology, both axles are drive-locked to the VTB cam, yet can still rotate independently of each other (unlike a Spool), similar to a regular Helical LSD. Due to being in a 100% constant state of torque-biasing, the MFactory VTB LSD will function both on & off throttle, similar to a Plate-type LSD.

By changing the ramp angles on the cam, the ramp-up response rate can also be fine-tuned. Whilst the maximum pre-load amount will not change, a more aggressively angled ramp will pre-load the system quicker, resulting in a significantly increased amount of torque transferred to the wheels up to the maximum as determined by the TBR. Initially set at 35deg, we will be offering more aggressive angles in the near future.

The above comparison chart details the difference between a Non-Cam system (the majority of Torque Biasing Differentials), a Single-Cam system and a Dual-Cam system (OZ Performance Drivetrain VTB System). As can be seen from the chart, a Single-Cam system has significant issues with ramp-up response and how it delivers pre-load into the system. So much so that even a Non-Cam system will provide smoother and more predictable power delivery to the wheels, provided there isn't a low-load/zero-load situation occurring. The dotted lines on the Dual-Cam graph give an example of more aggressive ramp-up response angles.

No-Load/One-Wheel Syndrome

A common misconception is that a torque-biasing Differential is useless under a no-load situation (e.g One wheel in the air). Although true to an extent, this no-load situation does not apply to the modern day car with Traction Control (or eDiff). For those without traction control, there is a very commonly used solution to the problem (used by professional race car drivers over the past 30+ years) that our competitors will not tell you; simply left-foot brake. Of course, with the MFactory VTB LSD, this is not an issue, with or without traction control due to our use of Dual-Pulsing cam technology.

Additionally, a Single-Cam system will only function consistently on one wheel during a low-load/zero-load situation, dependent on which axle the cam is driving. Due to the opposing axle functioning via a friction-based mechanism, this is rather hit-and-miss, as proven by real-world performance reviews. In most FWD vehicles, the cam will be driving the left axle (right axle on Honda B-Series). What this means is that, if your right axle (left axle on Honda B-Series) is subject to a low-load/zero-load situation, there is a significant chance of losing all power to your drivetrain, similar to a Non-Cam torque-biasing differential or Open Differential. With a Dual-Cam system, this will never be an issue as drive will always be provided to both axles, much like a Plate LSD would.

|

* Legal Disclaimer

Unfortunately, due to a legal dispute with a certain US Company, all sales within the United States, Australia and Japan will have the Dual-Pulsing cam technology disabled until the legal situation is resolved. To cut the story short, the patent concerned is so generalised and ridiculous that it's similar to Ford® suing Honda® for also making an automobile, even though the design, functionality and outcome is so fundamentally different it's like comparing Apples & Oranges (both are a fruit, but that is it). Whilst MFactory Competition Products do not recommend and wholeheartedly advise against doing this (we 100% abide by the International Patent Laws), the Dual-Pulsing cam technology may be re-enabled by sourcing the specific cam components and modifying your LSD before installing/reinstalling the LSD (this applies to all Torque Biasing LSD's that utilise the OZ Performance Drivetrain VTB System). While it may be possible to source these components outside the United States/Australia/Japan or even directly via OZ Performance Drivetrain of Australia, MFactory Competition Products holds no legal liability if you do so, will not provide instructions on how to modify your LSD and in no way, shape or form endorses this modification. Consumers would proceed at their own risk. All testing & development on test samples thus far have been conducted within the Peoples Republic of China, the Republic of China and the United Kingdom of Great Britain and Northern Ireland. No development work on the MFactory VTB LSD has taken place within the territories of the United States, Australia or Japan. |

The MFactory VTB LSD is the ONLY Helical LSD on the market that is a true hybrid of a Helical LSD (smoothness, noise-free, maintenance-free) and a Plate-type LSD (variable torque/load settings, increased traction under most situations).

- Patent-pending VTB System by OZ Performance Drivetrain of Australia

- Cam angles can be swapped out to fine-tune ramp-up response rate

- Custom made coil-springs by Swift Springs of Japan

- Coil-springs can swapped out with different Spring Rates to fine-tune torque-bias

To enhance durability whilst minimising frictional losses, all MFactory VTB LSD's incorporate our proprietary nano-coated discs between the gears and LSD housing. Whilst most common Helical and Plate-type LSD's on the market will lose performance over time, the MFactory VTB LSD will provide the same level of performance over the lifetime of the LSD. And, unlike our competitors that use Carbon as their go-to friction material, our proprietary nano-coated discs only marginally reduce the friction co-efficient. Torque-biasing differentials by design rely on friction to generate torque, therefore using Carbon friction material to reduce friction by several magnitudes is truly a very bad idea. Infact, a mere 0.1 reduction in friction co-efficient is equivalent to a 10% reduction in TBR.

Hybrid Ceramic Bearing Technology (Application Dependant)

Depending on application, the MFactory VTB LSD will be supplied with our new Hybrid Ceramic Diff Bearings. Not only are our bearings stronger and more durable, they also offer the epitome of near-zero rotational friction, minimizing parasitic drivetrain losses, thus transferring more power to the ground!

3rd Generation Design

The MFactory VTB LSD is lighter, stronger and more efficient than any other Torque-Biasing Differential on the market today!

VTB System Upgrade (Application Dependant)

Already run a regular Helical LSD and were thinking of upgrading? For select applications, we are proud to offer our patent-pending VTB System as an independent aftermarket upgrade to existing MFactory Helical LSD's. The upgrade kit includes: VTB System + VTB Gears + New Case Bolts.

Diamond Cut to exacting tolerances from Forged High-Nickel-Chromium-Molybdenum Steel

Perfect fitment & finish ensures hassle-free installation & maintenance, each and every time.

Designed using leading-edge Solidworks 3D CAD & Cosmos FEA software

Advanced Gear Geometry minimizes parasitic drivetrain losses. Race transmissions built with MFactory components transfer, on average, 1-2% more power to the ground over our competitors!

Covered by the MFactory Lifetime, Globally Transferable Warranty

Whether used on the Street, Strip or Track, all MFactory VTB LSD's come with a Lifetime, No-Hassle, Globally Transferable Warranty.

Maintain a leading advantage over the competition with the patent-pending MFactory "Variable Torque Biasing" Limited Slip Differential. Through the smooth and constant distribution of power to the wheels, the MFactory VTB LSD puts the power-to-the-ground and maximises your vehicle's traction. A must for any race car, be it Street, Strip or Track!

Specifications

- Made from imported Japanese SAE 4320 & SAE 9310 Steel

- Forged, Double Tempered and Super Sub-Zero treated for unsurpassed toughness

- Advanced Shot Peening technology increases surface hardness

- Designed to withstand the extreme shock loads of competition-level Drag Racing

- Advanced gear geometry designed using industry-leading software puts more power to the ground

- Only the highest quality Brighton-Best Hardware is used

- Maintenance-free Gears eliminates the need for special fluids & rebuilds associated with Plate-type LSDs

- Smooth Helical Gear operation ensures no adverse affect to steering response, unlike with Plate-type LSD's

Honda B16A2 Fitments: Will not directly fit models previously equipped with an OEM Viscous LSD, and will require a Ring Gear change

BMW 135i MT/335i 07+ MT/DCT/335d Fitments: Will not directly fit these models due to the oem Ring Gear being welded onto the differential. The Ring Gear will either need to be machined to accept the new LSD, or a new bolted Ring & Pinion used. MFactory Competition Products is one of only 3 companies in the US that can provide this service that meets oem tolerances, and the only US company to manufacture precision aftermarket performance Ring & Pinions (Final Drive Gears) for the BMW

PLEASE NOTE:

Our VTB LSD is still under development and is not yet ready to be released to market. Please Contact Us for an ETA before placing your order

MFactory Competition Products will provide a limited lifetime warranty for all VTB LSD's to be free of defects in materials and workmanship upon receipt of product and professional installation. Parts returned must be determined by MFactory Competition Products to be defective before any warranty credit or replacement is issued

MFactory Competition Products's obligation under warranty shall be limited to repairing or replacing, at its option, any part proven defective. The customer must prepay transportation charges

Final determination of the suitability of the products for the use contemplated by the buyer is the sole responsibility of the buyer. MFactory Competition Products shall not be liable for any special, direct, indirect, incidental, or consequential damages, that might be claimed as a result of the failure of any part, including claims for delay, loss of profits, or labor

MFactory Competition Products shall not be liable for any damage or injury to persons or property resulting from improper installation or misuse of any part subject to this warranty

There are no other warranties expressed or implied extending beyond those set forth above

INSTALLATION: Any warranty claims arising as a result of the failure of a VTB LSD will ONLY be entertained if the LSD was professionally installed.

RECOMMENDED BEARINGS: When ordering your MFactory VTB LSD, we highly recommend that you order our new Hybrid Ceramic Diff Bearings at the same time.

MFactory Competition Products's obligation under warranty shall be limited to repairing or replacing, at its option, any part proven defective. The customer must prepay transportation charges

Final determination of the suitability of the products for the use contemplated by the buyer is the sole responsibility of the buyer. MFactory Competition Products shall not be liable for any special, direct, indirect, incidental, or consequential damages, that might be claimed as a result of the failure of any part, including claims for delay, loss of profits, or labor

MFactory Competition Products shall not be liable for any damage or injury to persons or property resulting from improper installation or misuse of any part subject to this warranty

There are no other warranties expressed or implied extending beyond those set forth above

INSTALLATION: Any warranty claims arising as a result of the failure of a VTB LSD will ONLY be entertained if the LSD was professionally installed.

RECOMMENDED BEARINGS: When ordering your MFactory VTB LSD, we highly recommend that you order our new Hybrid Ceramic Diff Bearings at the same time.